陶瓷纤维折叠块

High temperature blanket module

产品描述:

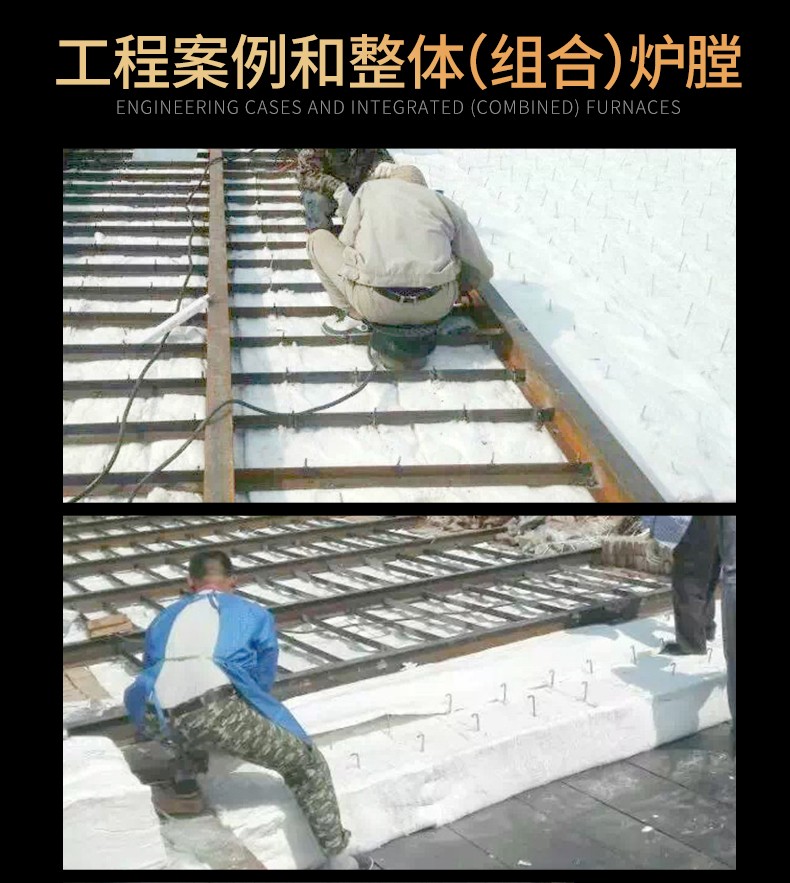

陶瓷纤维折叠模块是选用陶瓷纤维针刺毯,经先进的专用设备,通过折叠,加装锚固件和其他附件困扎而成。本产品是工业窑炉最常用的绝热模块,由于纤维模块处于压缩状态,在使用安装完毕后,模块因纤维的回弹而膨胀,使炉衬无缝隙,抵消了纤维的热收缩,提高了纤维炉衬的绝热性能。根据使用环境的不同。可在模块工作面涂上表面处理剂,提高模块的使用性能。

product description:

Ceramic fiber folded module is the choice of ceramic fiber blanket acupuncture, the advanced equipment, by folding, the installation of anchors and other accessories sleepy tie together. This product is the most commonly used industrial furnace insulation module, the fiber module in a compressed state, in use after installation, the module due to the expansion of fiber rebound and make seamless lining, offset the heat shrinkage fiber, improved fiber lining thermal insulation properties. Depending on different environments. It can be coated with a surface treatment agent module Face, and improve the performance of the module

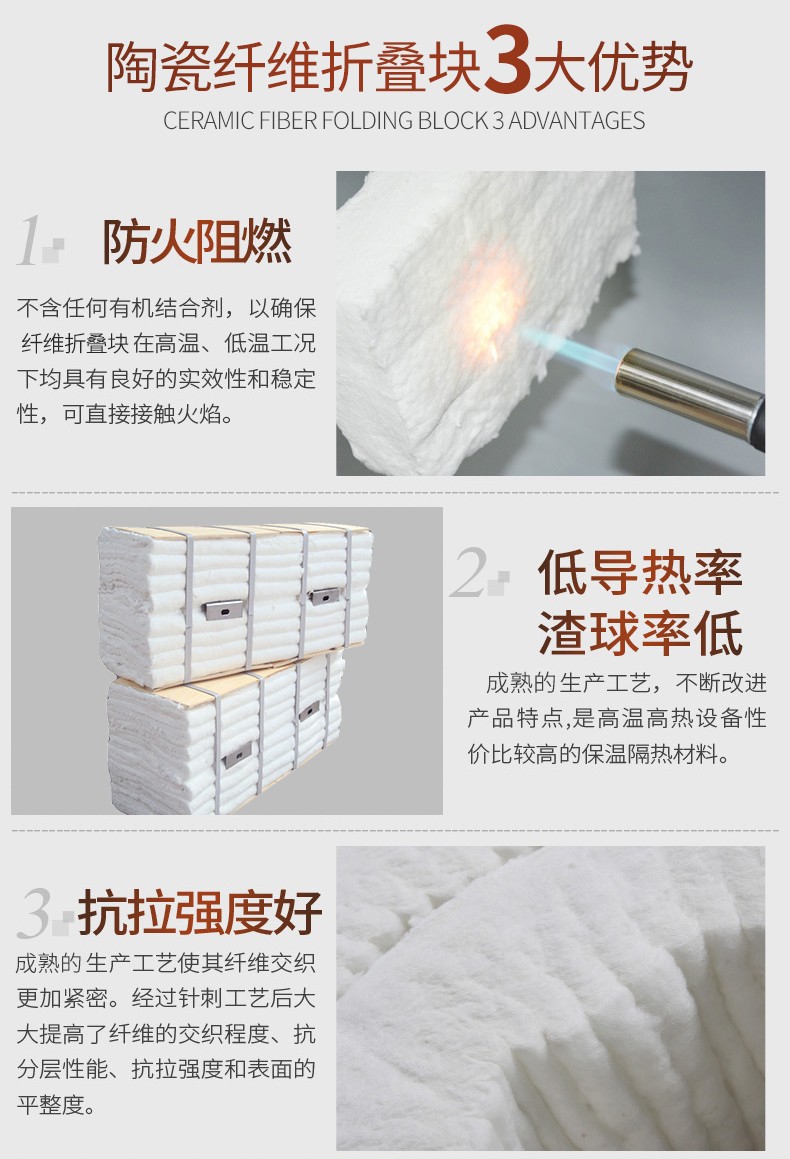

产品特点:

低容重、低导热率;优良的热稳定性、抗热震性;优良的回弹性;机械强度高;施工安装方便;

Features:

Low bulk density, low thermal conductivity; excellent thermal stability, thermal shock resistance; excellent elasticity; high mechanical strength; convenient construction and installation;

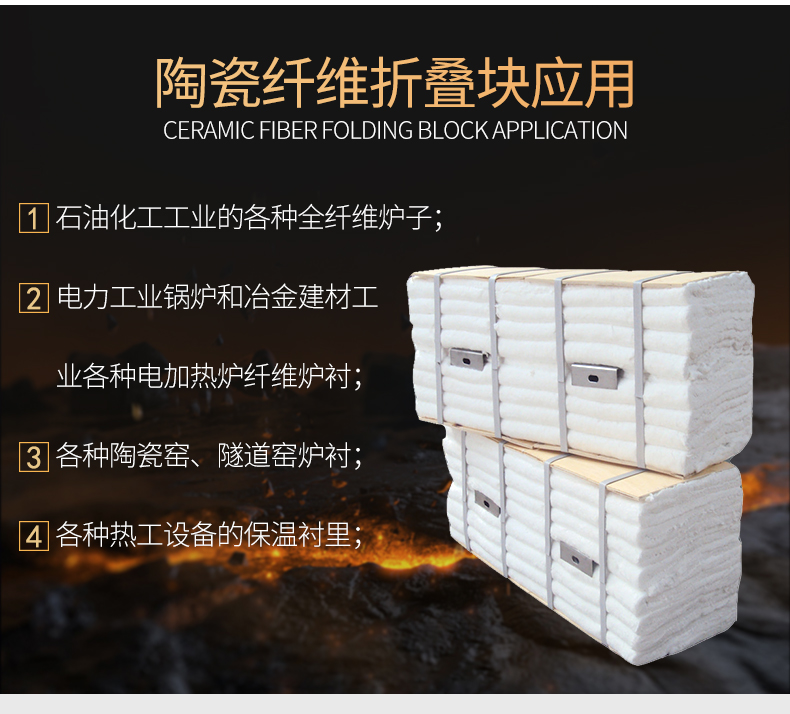

产品应用:

石油化工工业的各种全纤维炉子;电力工业锅炉和冶金建材工业各种电加热炉纤维炉衬;各种陶瓷窑、隧道窑炉衬;各种热工设备的保温衬里;

Applications:

Various full fiber furnace petrochemical industry; industrial boilers and power metallurgy and building materials industry a variety of electric furnace fiber lining; various ceramic kiln, tunnel kiln lining; lining of various thermal insulation devices;

产品性能:Performance:

规格参数Specifications | GWDL-W1100 | GWDL-W1200 | GWDL-W1300 | GWDL-W1400 | GWDL-W1400 | ||

类别 | 普铝 | 高纯 | 高铝 | 含锆 | 多晶 | ||

长期使用温度(炉温),℃ Long-term service temperature℃ | 1100 | 1200 | 1300 | 1400 | 1600 | ||

加热线变化,% Linear shrinkage on heating | 1000×24h≤-3 | 1100×24h≤-3 | 1200×24h≤-3 | 1350×24h≤-3 | 1550×24h≤-3 | ||

理论导热系数W/(m·k)(128kg/m³) | 平均500℃ | ≤0.153 | ≤0.153 | ≤0.153 | ≤0.153 | ||

抗拉强度(Mpa)(25mm) | ≥0.04 | ≥0.05 | ≥0.04 | ≥0.06 | ≥0.06 | ||

体积密度(Kg/m³) | 160-260 | 160-260 | 160-260 | 160-260 | 160-260 | ||

化学成分(%)Chemical compositions(%) | Al₂O₃ | ≥44 | ≥45 | ≥52 | ≥36 | ≥72 | |

SiO₂ | ≥52 | ≥54 | ≥46 | ≥48 | ≥28 | ||

Al₂O₃+ SiO₂ | ≥97 | ≥99 | ≥99 | —— | —— | ||

Fe₂O₃ | ≤0.8 | ≤0.2 | ≤0.2 | ≤0.1 | —— | ||

ZrO₂ | —— | —— | —— | ≥15 | —— | ||

ZrO₂+ Al₂O₃+ SiO₂ | —— | —— | —— | ≥99 | ≥99 | ||

包装形式package style | 塑料袋+纸箱Bag + carton | ||||||

注:产品的技术数据是由所采用的测试标准得的平均值,会在一定的范围内波动,该数据不代表产品的质量保证数据。

陶瓷纤维折叠块

High temperature blanket module

产品描述:

陶瓷纤维折叠模块是选用陶瓷纤维针刺毯,经先进的专用设备,通过折叠,加装锚固件和其他附件困扎而成。本产品是工业窑炉最常用的绝热模块,由于纤维模块处于压缩状态,在使用安装完毕后,模块因纤维的回弹而膨胀,使炉衬无缝隙,抵消了纤维的热收缩,提高了纤维炉衬的绝热性能。根据使用环境的不同。可在模块工作面涂上表面处理剂,提高模块的使用性能。

product description:

Ceramic fiber folded module is the choice of ceramic fiber blanket acupuncture, the advanced equipment, by folding, the installation of anchors and other accessories sleepy tie together. This product is the most commonly used industrial furnace insulation module, the fiber module in a compressed state, in use after installation, the module due to the expansion of fiber rebound and make seamless lining, offset the heat shrinkage fiber, improved fiber lining thermal insulation properties. Depending on different environments. It can be coated with a surface treatment agent module Face, and improve the performance of the module

产品特点:

低容重、低导热率;优良的热稳定性、抗热震性;优良的回弹性;机械强度高;施工安装方便;

Features:

Low bulk density, low thermal conductivity; excellent thermal stability, thermal shock resistance; excellent elasticity; high mechanical strength; convenient construction and installation;

产品应用:

石油化工工业的各种全纤维炉子;电力工业锅炉和冶金建材工业各种电加热炉纤维炉衬;各种陶瓷窑、隧道窑炉衬;各种热工设备的保温衬里;

Applications:

Various full fiber furnace petrochemical industry; industrial boilers and power metallurgy and building materials industry a variety of electric furnace fiber lining; various ceramic kiln, tunnel kiln lining; lining of various thermal insulation devices;

产品性能:Performance:

规格参数Specifications | GWDL-W1100 | GWDL-W1200 | GWDL-W1300 | GWDL-W1400 | GWDL-W1400 | ||

类别 | 普铝 | 高纯 | 高铝 | 含锆 | 多晶 | ||

长期使用温度(炉温),℃ Long-term service temperature℃ | 1100 | 1200 | 1300 | 1400 | 1600 | ||

加热线变化,% Linear shrinkage on heating | 1000×24h≤-3 | 1100×24h≤-3 | 1200×24h≤-3 | 1350×24h≤-3 | 1550×24h≤-3 | ||

理论导热系数W/(m·k)(128kg/m³) | 平均500℃ | ≤0.153 | ≤0.153 | ≤0.153 | ≤0.153 | ||

抗拉强度(Mpa)(25mm) | ≥0.04 | ≥0.05 | ≥0.04 | ≥0.06 | ≥0.06 | ||

体积密度(Kg/m³) | 160-260 | 160-260 | 160-260 | 160-260 | 160-260 | ||

化学成分(%)Chemical compositions(%) | Al₂O₃ | ≥44 | ≥45 | ≥52 | ≥36 | ≥72 | |

SiO₂ | ≥52 | ≥54 | ≥46 | ≥48 | ≥28 | ||

Al₂O₃+ SiO₂ | ≥97 | ≥99 | ≥99 | —— | —— | ||

Fe₂O₃ | ≤0.8 | ≤0.2 | ≤0.2 | ≤0.1 | —— | ||

ZrO₂ | —— | —— | —— | ≥15 | —— | ||

ZrO₂+ Al₂O₃+ SiO₂ | —— | —— | —— | ≥99 | ≥99 | ||

包装形式package style | 塑料袋+纸箱Bag + carton | ||||||

注:产品的技术数据是由所采用的测试标准得的平均值,会在一定的范围内波动,该数据不代表产品的质量保证数据。

-

陶瓷纤维材料宣传册.pdf文件大小:4.67M下载

陶瓷纤维材料宣传册.pdf文件大小:4.67M下载